Recovering Hydrogen for Urea, Nutrients for Organic Fertiliser and Power

from Biomass and Waste

Clever Power is an Australian company focused on new ways to utilise waste.

Powering the Circular Economy

How does it work?

-

Syn-Gas

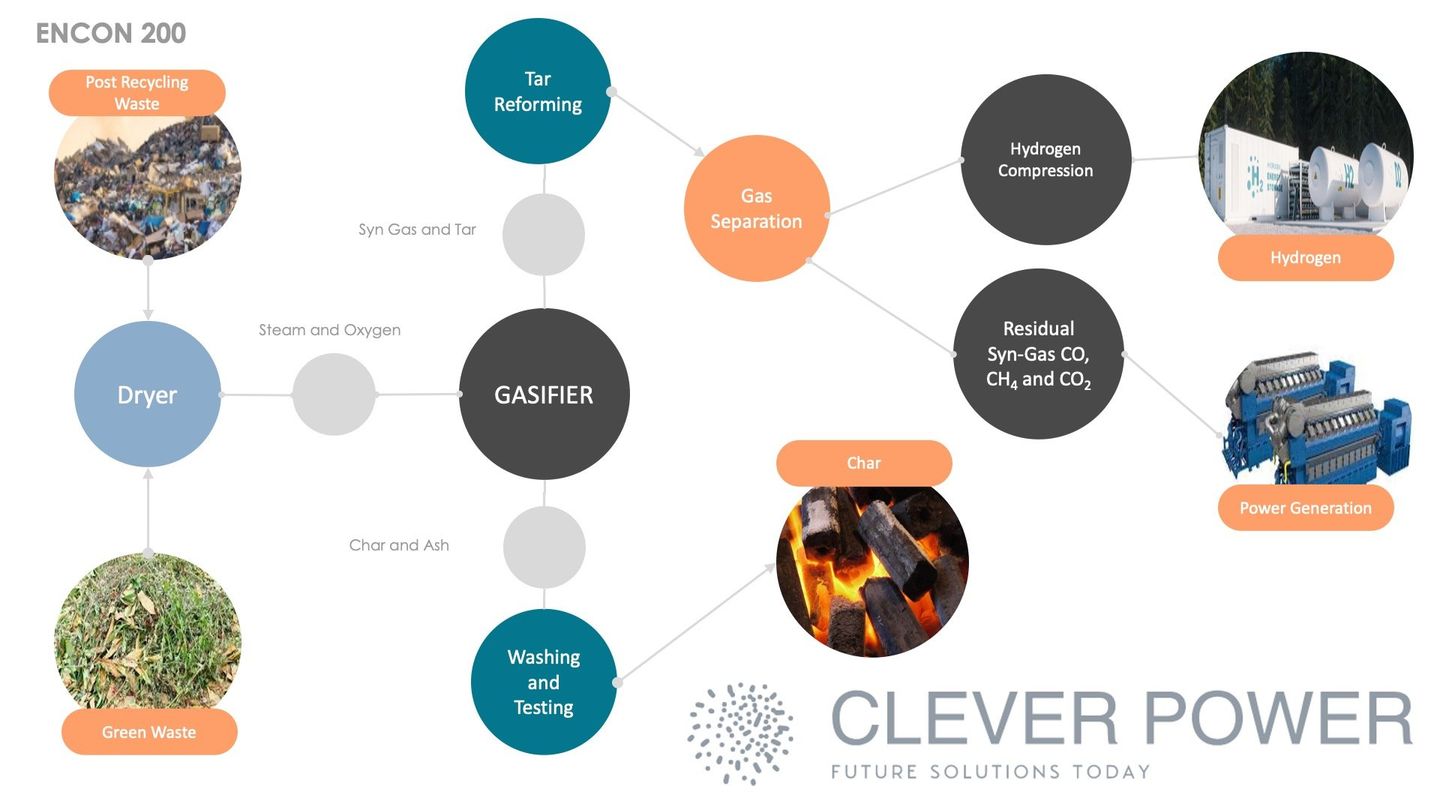

The ENCON 200 energy conversion plant heats a mixture of Refuse Derived Fuel (RDF) and green waste or green waste by itself to produce syn-gas.

Syn-gas is a mixture of H2, CO, H2O, CO2, CH4, N2 and tarry oils. The syn-gas is scrubbed in our patented process so that it burns extremely cleanly.

-

Electricity Production

Both gas and turbine engines produce electricity. The CO and CH4, left over after the hydrogen recovery, is used to generate power.

On certain projects the waste heat from the gas engines or gas turbines are collected and used to generate steam. The steam can be used to generate further electricity or for heating processes like drying, distillation or cooling via an absorption chiller. In this way, the plant can use up to 75% of the original energy for beneficial use.

This is called co-generation or trigeneration. The electricity can be either sold to the grid, or to neighbours in the hydrogen hub or used to generate more hydrogen via electrolysis or used to charge batteries that can be leased for off-grid events.

-

Biochar

The char and ash can be made into fertilizer with some extra equipment to compost biomass and manure.

-

Fertiliser Production - Nutrient Recovery

Macro and micro nutrients can be recovered from biomass and waste. The waste heat from power generation can be use to sterilise and de-odourise composted mnaures. Wastes can be turned into slow release organic feriliser.

-

Circular Economy Benefits

The energy conversion process supports and enables the circular economy by allowing the waste delivery trucks and vehicles to be powered by the hydrogen generated from waste. The nutrients such as potassium and phosphorous, and trace nutrients like iron, zinc, calcium and magnesium in the biomass is recycled into new organic-rich soil which efficiently removes all the pathogens, weed seeds and sharp objects from the material.

-

Soil and water contamination destruction

The emission control process can also be used to treat tarry-organic and halogenic-organic compounds like PFAS.

-

Hydrogen Recovery

Hydrogen is recovered from the syn-gas as required before combustion. The syn-gas, minus any recovered hydrogen, is then burnt in a gas engine (like a diesel with spark plugs) or on larger projects a gas turbine (like a jet engine).

Clever Power's Vision

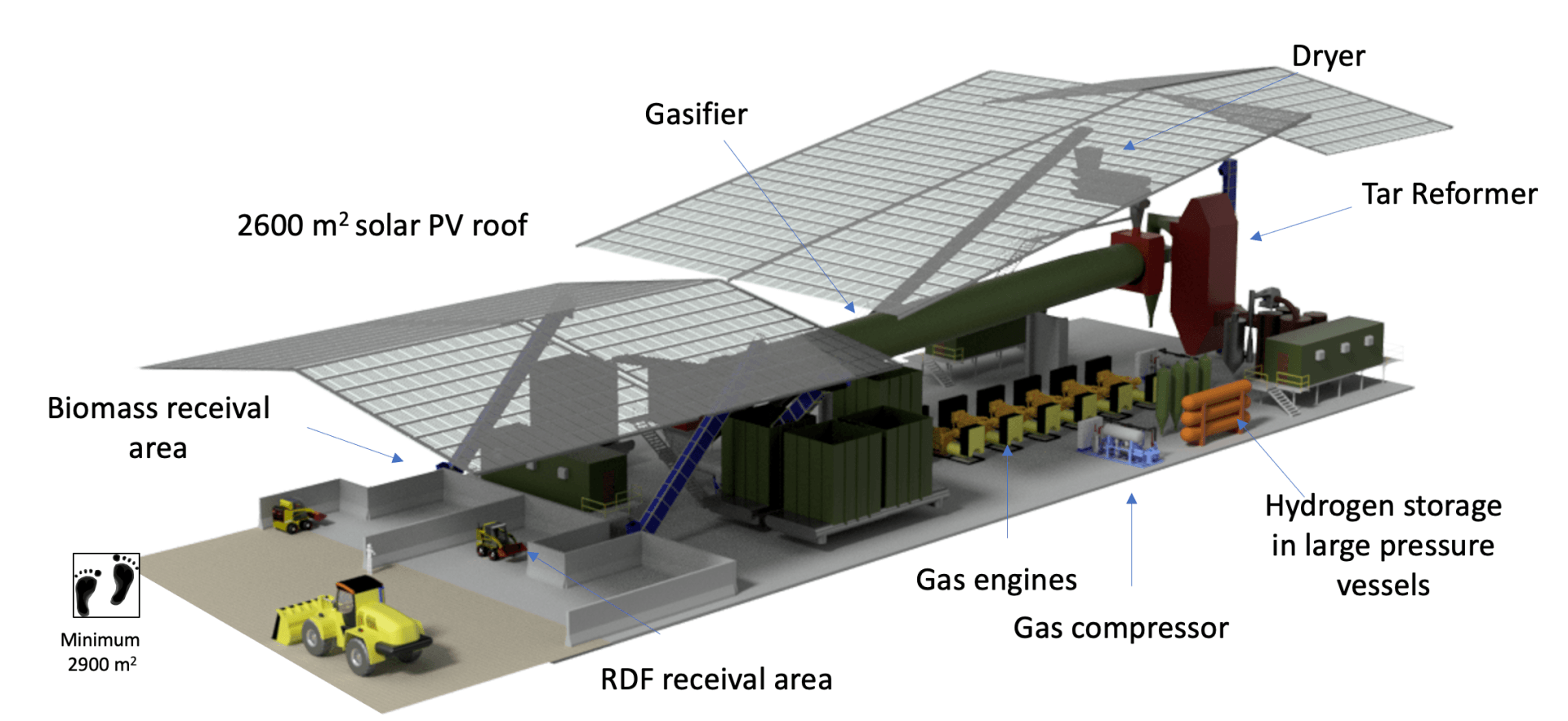

The design process begins with a standard plant model, like the ENCON200 shown in the video above. This design will be customised to your energy needs.

Working with our team of engineers and scientists, Clever Power helps you recover resources from your waste. Our focus is on converting waste into new products whilst minimising energy loss, thus powering the circular economy.

“We drive the new use of waste by asking ourselves one question – “What if we use our waste to generate useful products?”

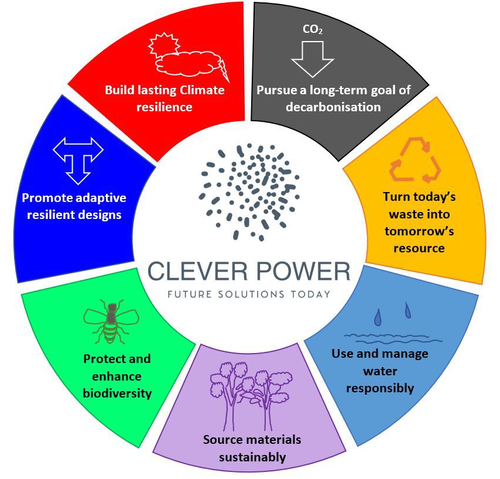

- Pursue a long-term goal of decarbonisation:

Our process results in a significant reduction in carbon. Our 200 t/d energy conversion plant represents a:

· 241 t/d of CO2 equ. drop in net emission compared to conventional landfill,

· 116 t/d of CO2 equ. drop in net emission compared to a conventional waste to energy plant,

· 81 t/d of CO2 equ. drop in net emission compared to a conventional landfill with methane capture and combustion

- Turn today’s waste into tomorrow’s resource:

Clever Power considers all waste a potential resource. Our process uses waste efficiently.

Waste is used to produce hydrogen (a resource) profitably at 60% of the cost of solar PV and electrolysis

- Use and manage water responsibly:

Our process uses almost half of the water use of electrolysis to produce Hydrogen.

Process water will be harvested from storm water and treated on site.

- Source materials sustainably:

The plant construction uses glue-laminated wood beams instead of structural steel.

To further the goals of sustainability Geopolymer concrete will be used instead of Portland cement concrete, clay bricks and pavers will be used instead of concrete based masonry.

Also, the feed stock biomass is sourced from waste and will not be sourced from food crops.

Only post recycling waste will be used, that is all the economically recoverable metal, glass, plastic, paper and cardboard is removed.

Batteries used in this plant have no cobalt.

- Protect and enhance biodiversity:

Clever Power is committed to:

· Reducing our demand for resource and

· Reusing, recycling and recovering to produce renewed resources

· Using the lowest possible air water and land emission technology

· Using renewable energy

· Make agricultural land more productive by recycling nutrients so there is no need to remove forest, scrub, or reclaim swamps

· Encourage permaculture

· Target weeds as feedstock

By following these principles Clever Power will protect and enhance biodiversity.

- Promote adaptive resilient designs:

Our energy conversion plant is an example of adaptive resilient design in that it can be optimised between hydrogen, power, fertilizer, soil remediation and process steam.

The plant is adaptable to future energy requirements.

- Build lasting climate resilience

Climate change adaptation and interventions cannot achieve sustainable results without dealing with the fundamental root causes of poverty and vulnerability. This is why Clever Power’s is committed to philanthropic causes. Clever Power continues to work with

- Pacific Islanders who are vulnerable to rising sea levels and where landfill leachate kills the coral reefs,

- Sub-Sahara Africanis where 53% of the population lacked access to electricity hence agriculture is dependent of hand-carried water in drought and refrigeration is not available, and in

- India where there is a commitment to leave no one behind. Waste reduction and useable energy is key to helping these societies.

Notes from the Founder

The ENCON200 aims to convert waste commercially and safely into hydrogen, nutrients, electricity, and local heating and cooling.

Our main goals are to convert waste that can be diverted from landfill . We immediately can reduce CO2 equivalent emissions from those landfills.

Most of the energy we produce is secured from renewable sources. In spite of the non-renewable contamination, the net impact is very positive towards the goal of de-carbonising our future energy demands.

David Cork

Talk to us Today!

Contact Us

We will get back to you as soon as possible

Please try again later